The three-roll planetary rolling mill is the most critical equipment in the copper tube casting and rolling production line. This equipment achieves a single-pass deformation rate exceeding 90% (elongation coefficient: 12–16), and the rapid compression process increases the temperature of the material to the point where dynamic recrystallization occurs. The rolled tube acquires fine equiaxed grains and remains in a soft state, providing excellent stretchability and superior wall thickness tolerance for subsequent drawing processes.

The latest-generation RM-90 /100 three-roll planetary rolling mill, developed by Clabo features optimized design and improvements, delivering high single-machine productivity, stable operation, and world-leading technical performance. Key features include:

Extended roller head lifespan through continuous design improvements. One set of roller heads can produce over 10,000 tons of copper tubes, requiring only replacement of wear parts like seals and bearings.

Enhanced cooling system improves roll life by optimizing temperature and friction conditions in the deformation zone. Efficient cooling also ensures refined grain structure in copper tubes.

Two operating modes: semi-automatic rolling and continuous automatic rolling.

Automatic online terminal cutting and hole-expanding devices significantly reduce labor requirements.

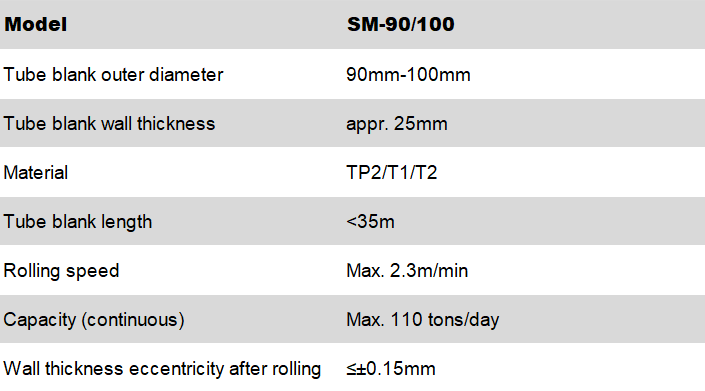

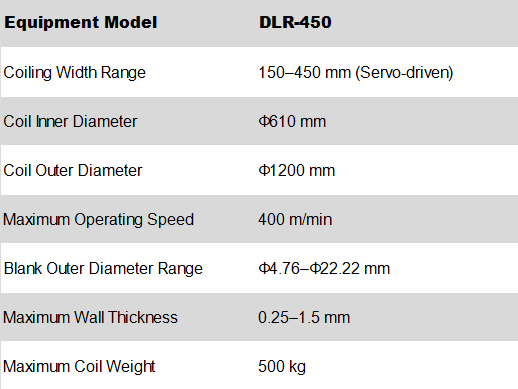

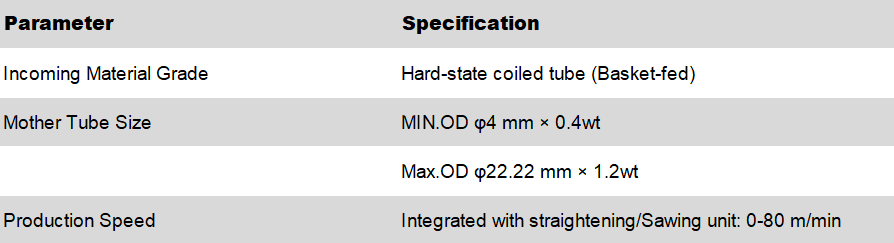

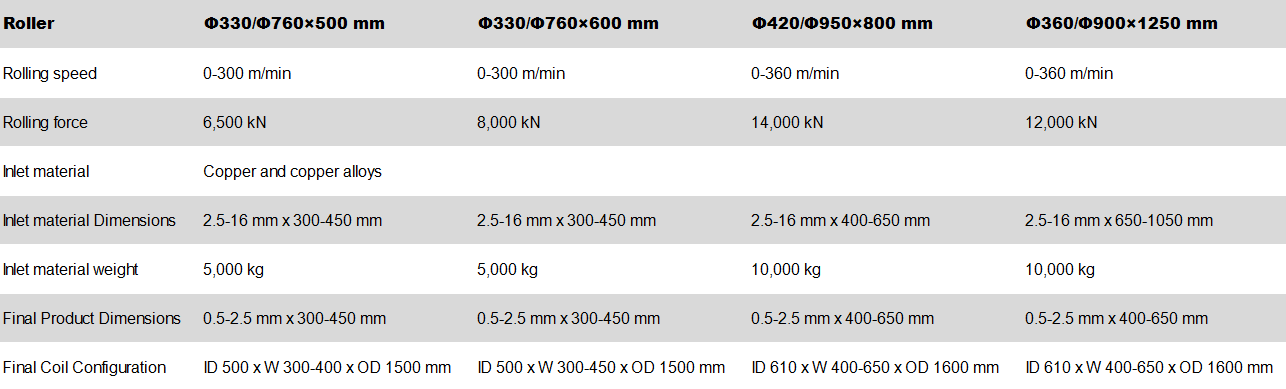

Main Technical Parameters of Three-Roll Planetary Rolling Mill

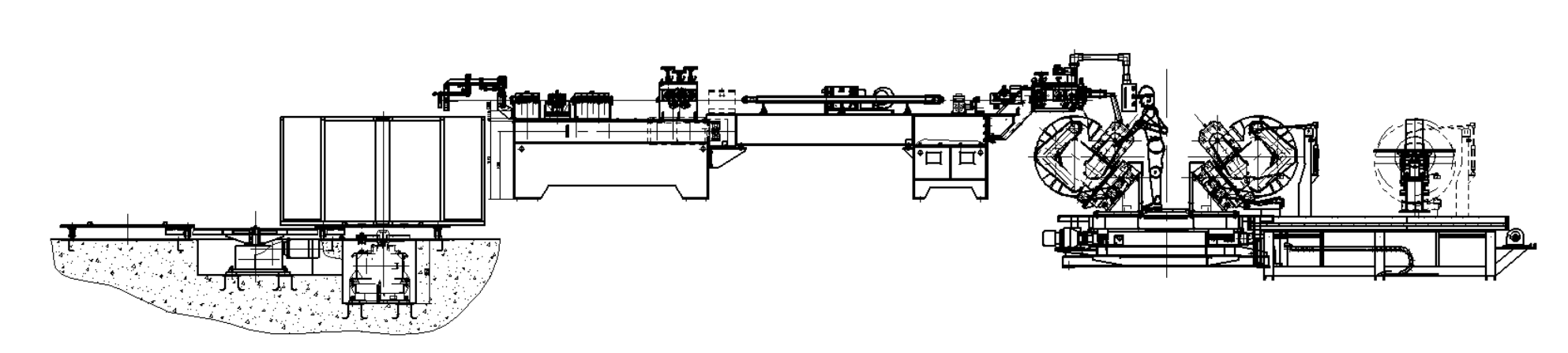

The new-generation Surface Milling Machine developed by CLABO serves as specialized equipment for removing oxide scale from the outer surface of tube blank in copper tube casting and rolling lines. It employs a straightening and milling surface technology, which is protected by independent intellectual property rights, to remove the oxide scale in a single pass. This significantly enhances both product yield and milling surface quality. The unit comprises a feeding system, planetary milling machine, discharging system, and is integrated with corresponding electronic control, hydraulic, lubrication, pneumatic, and cooling systems.

Main Features of the Equipment:

(1) One-key operation enables the automatic milling process, including feeding, milling, and discharging.

(2) The application of straightening and sizing technology ensures excellent straightness and roundness of the tube blank while minimizing the milling volume.

(3) An optimized internal and external guiding system eliminates vibration during milling, resulting in superior roundness and high surface quality of the finished products.

(4) The milling cutter is infinitely adjustable, allowing a single cutter to mill varying thicknesses of the tube blank’s surface.

(5) The copper chip collection device can be equipped with a drag chain walking mechanism featuring a drying function.

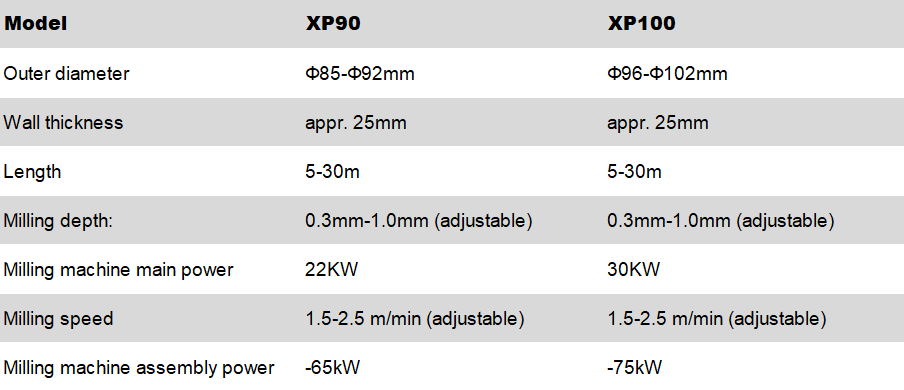

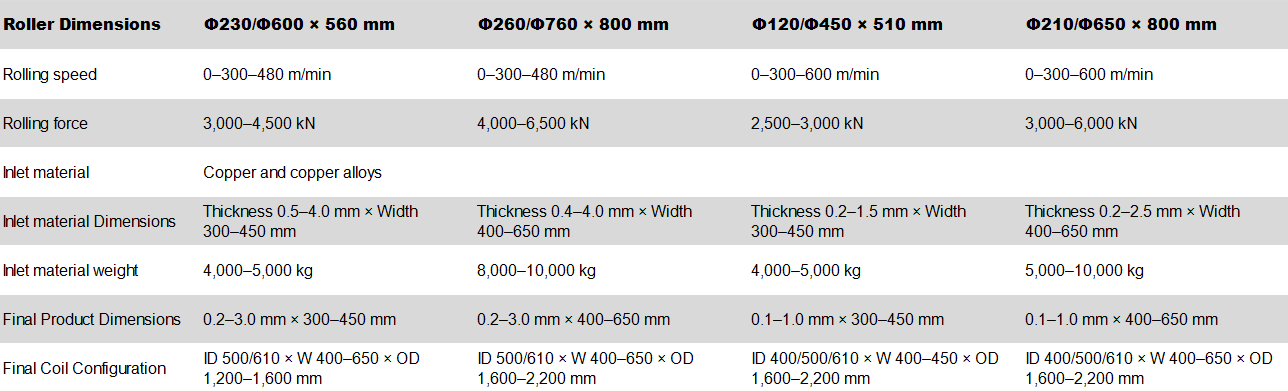

Key equipment parameters are provided below.

Mark: Customization can be made for different materials and outer diameters as per requirements.

The Cam-type Drawing Machine serves as a core component in copper tube continuous casting and rolling production lines. It fulfills dimensional and precision requirements through continuous reduction of diameter and wall thickness. With linear drawing capability, unlimited length processing capacity, and high single-pass efficiency, the machine can be configured as either U-type or linear cascade drawing units. The next-generation cascade drawing machine developed by Clabo demonstrates high precision, operational stability, and performance metrics aligned with international advanced standards.

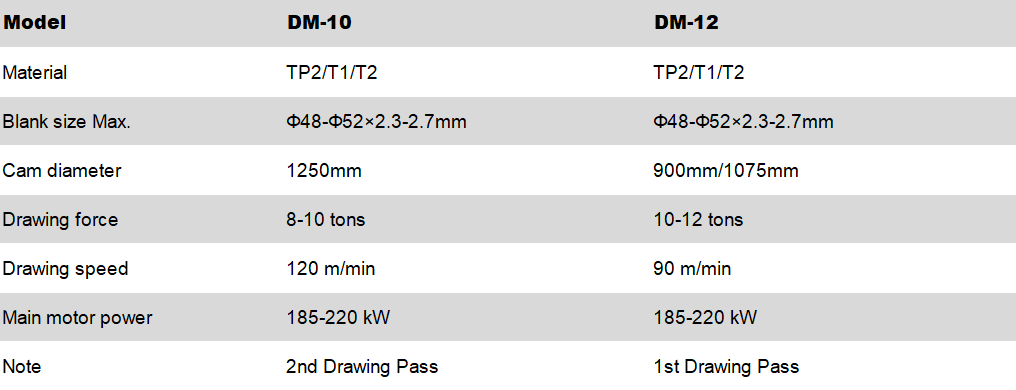

Technical Parameters for Copper Tube Continuous Casting and Rolling Process

DB-2200 Spinner Block is the latest independently developed tube drawing machine by CLABO. The design of the new machine is innovative, with the operating platform located on the outer side of the basket conveying track, making it easy for two (or more) machines to share a platform and enable one person to operate two (or more) machines; Both automation and production efficiency of the machine have been improved.

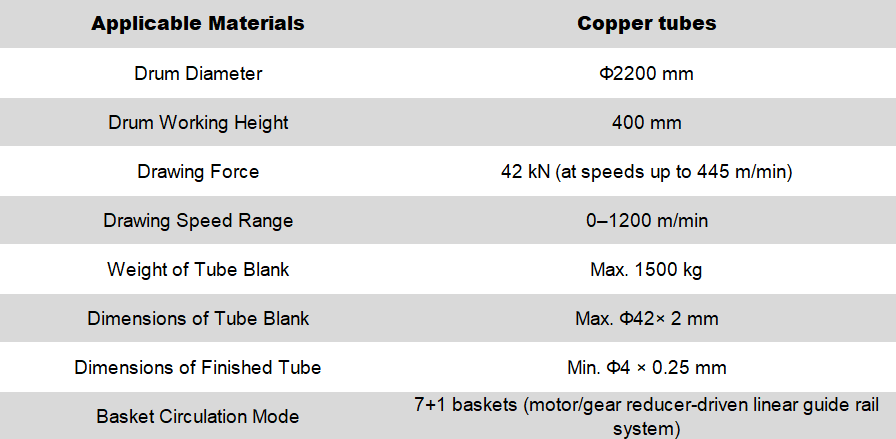

Ø2200 Spinner Block Technical Specifications

Level Re-winder is used to take the loose coils drawn to the required size by the Spinner Block and re-winds them into coils with specified inner diameter, outer diameter and thickness in accordance with technical requirements. The pre-bending, winding width adjustment, and wiring movement are precisely controlled by servo motors, enabling automatic center positioning of packing and winding origin alignment. Additionally, the system supports automatic unloading to the center without manual intervention. This equipment boasts high automation, simplified operation, and reduced labor intensity. Depending on the number of winding coils, it can be categorized into single-head and double-head re-winder configurations.

The key features of the equipment are as follows:

(1) Servo-controlled pre-bending roller, which can be automatically adjusted to match the curvature radius of winding.

(2) Servo-controlled roll width adjustment, enabling automatic adjustment of the roll width based on the screen-set value.

(3) Servo-controlled wiring movement, ensuring compact and aesthetically pleasing wiring.

Main equipment parameters

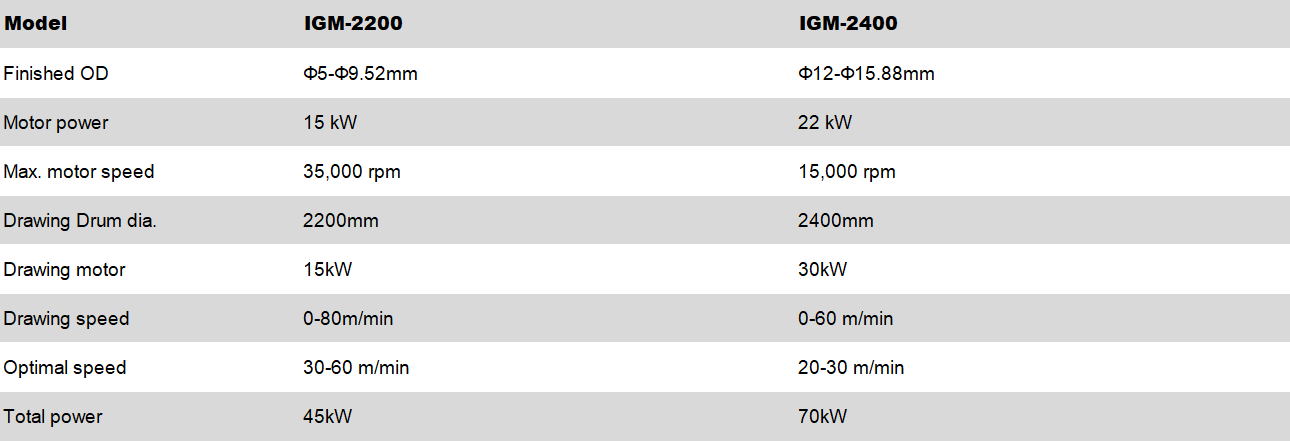

The IGM-2200 Inner Grooved Machine is a newly developed vertical block type inner groove shaping by Clabo. Integrated with a payoff unit, high speed motor, spinning forming unit, vertical block drawing mechanism, coil receiving unit, and control system, it is primarily designed for manufacturing inner grooved copper tubes with outer diameters ranging from Φ5 to Φ9.52 mm.

The IGM-2400 Inner Grooved Machine represents Clabo’s latest advancement in vertical block type grooving technology. Featuring the same integrated configuration—including a payoff unit, high speed motor, spinning forming, vertical block drawing, coil receiving , and control systems—it is specifically engineered for producing inner grooved copper tubes with outer diameters ranging from Φ12 to Φ15.88 mm.

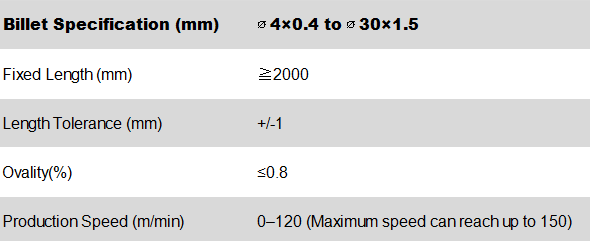

High-Speed Straightening and Sawing Machine

The high-speed straightening and Sawing machine is a specialized device that precisely cuts loose coiled tubes into straight tubes based on the preset length . It can be seamlessly integrated with an online pancake coiler and currently achieves the highest operational speed in industrial applications.

Main Features of the Equipment:

(1) Compact Design Structure

(2) Simplified Specification Replacement Process

(3) High Sizing Accuracy

(4) Advanced Degree of Automation

Key Equipment Parameters SS-30

The inverted pancake coiler is a specialized device designed for producing pancake coils. It utilizes servo control to accurately position the bending roller, ensuring consistent and orderly arrangement of the tube blank during the coiling process.

Main Features of the Equipment:

(1) Wide Range of Product Specifications

(2) Capable of Producing Multi-layer and Large-length Pancake Coils

The Inverted Capillary processing equipment is designed for drawing copper and aluminum capillary tubes. It is widely utilized in producing capillary tubes required for air conditioners, refrigerators, electronic components, and related industries.

Key Features

High-Capacity Continuous Production: Optimized for large-coil copper/aluminum tubing manufacturing. Reduces labor intensity, enhances efficiency, and supports heavy coil weights (up to 1+ tons).

User-Friendly Automation: Simple operation, low noise, reliable PLC-based control, high safety standards, and minimal maintenance requirements.

Integrated Pneumatic-Electric System: Coil drum equipped with cylinders, solenoid valves, and sensors, connected via pneumatic-electric slip rings for seamless external control.

Technical Parameters

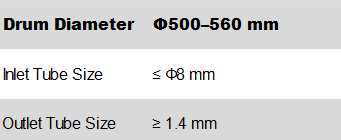

High-Speed Cold Pilger Mill

Our company has successfully developed a series of high-speed cold pilger mill machines designed for the production of precision cold-rolled tubes made from materials such as stainless steel, titanium, and titanium alloys. The finished tubes feature diameters ranging from Φ4 to Φ168 mm, wall thicknesses between 0.2 to 18 mm, surface roughness values of Ra ≤ 0.4–0.8 μm, and comply with international standards for shape and dimensional tolerances.

Clabo LG Series Two-Roll Cold Pilger Mills

Mark:

All models offer both stop-loading and continuous-loading versions. Process configurations allow either single/dual feeding and single/dual rotation as required.

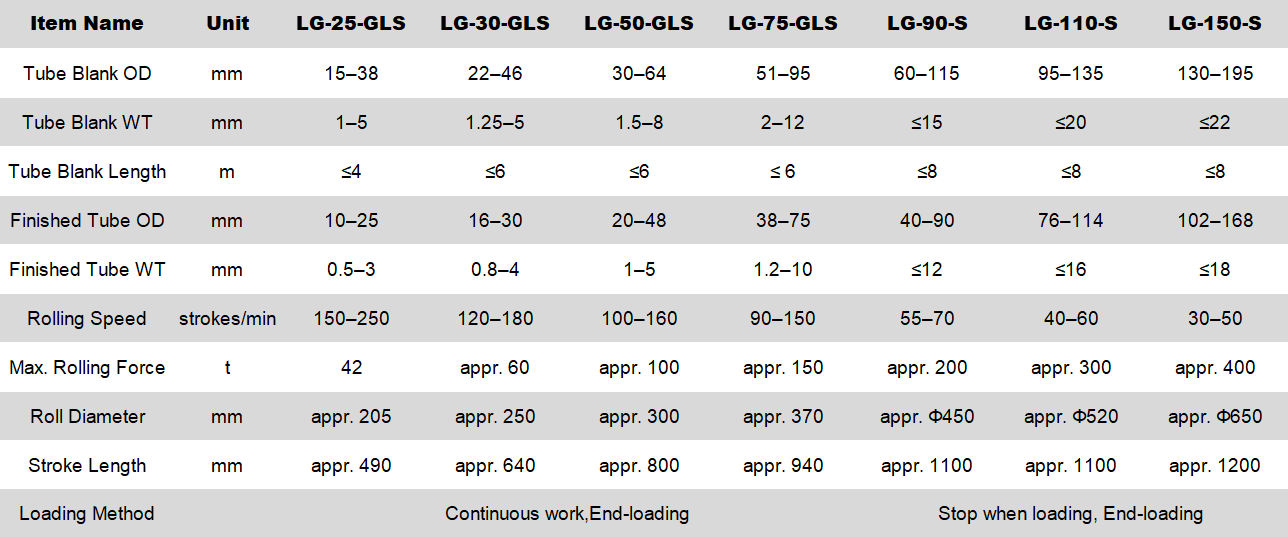

Clabo LD Series Multi-Roll Cold Pilger Mills

We specializes in manufacturing customized tube and bar straightening machines, providing straightening solutions and equipment. Key products include:

– Two-roller straightening: Features an upper concave and lower convex roller shape. Adjusting the roller angle changes the reverse-bending amount, suitable for bars and thick-walled pipes. Offers full-length straightening with a wide application range.

– Multi-roller straightening: Uses hyperbolic rollers to achieve reverse-bending through height differences. Common configurations: six rollers (2-2-2), seven rollers (2-2-2-1), ten rollers (2(5)), eleven rollers (2(5)-1). The seven-roller composite system (hyperbolic + deep/shallow concave rollers) is widely used for its superior straightening performance.

Working Principle of Roller-Type Straightening Machine

Round bars rotate and advance through a reverse-bending roller system. Uniform compressive bending deformation occurs in all circumferential directions, achieving straightening.

Key features:

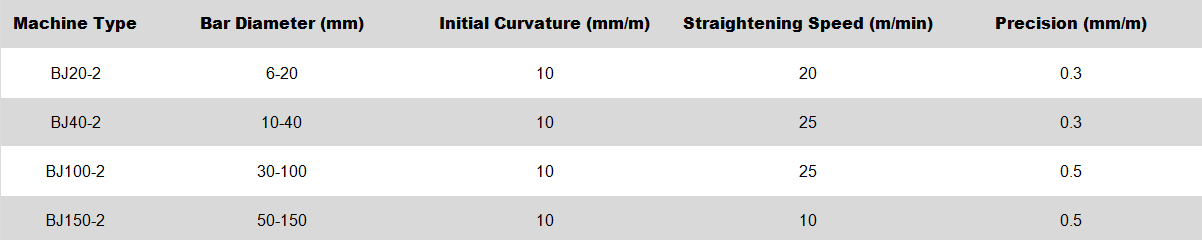

Two-Roller Bar Straightening Machine Parameters

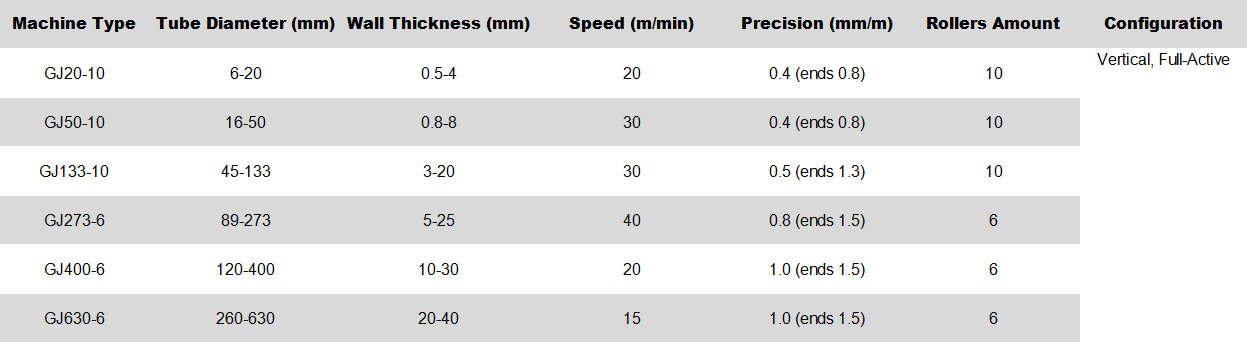

Multi-Roller Tube Straightening Machine Parameters

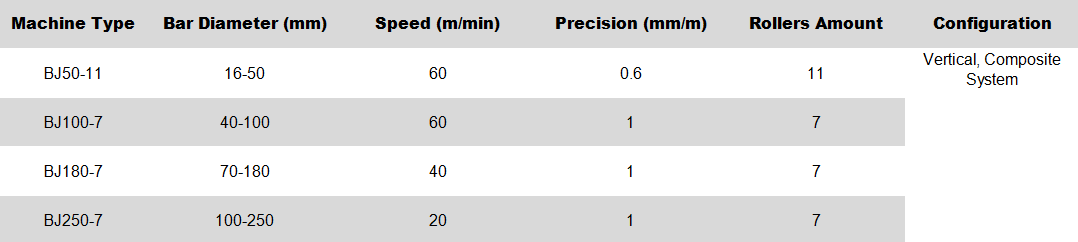

Multi-Roller Bar Straightening Machine Parameters

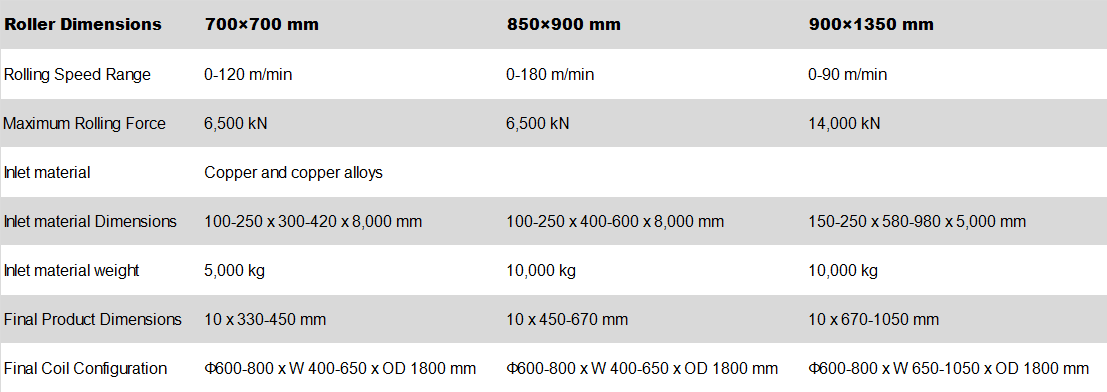

The Two-Roll Hot-rolling reversible Mill is primarily employed for the precision hot rolling of preheated copper and copper alloy ingots through bidirectional rolling passes. Following the rolling process, the produced plate is automatically coiled into finished coil form for further processing.

The four-roll hydraulic rough-to-medium rolling mill is specifically designed for the reversible cold rolling of annealed copper and copper alloys, followed by the formation of the finished products into coiled material for downstream processing.

Four-roll hydraulic intermediate-to-finishing rolling mill: This unit is specifically engineered for the reversible cold rolling of annealed copper and copper alloys, with the subsequent coiling of the processed material into finished coil products.

Copyright © 2025 HANYUAN·CLABO All Rights Reserved.