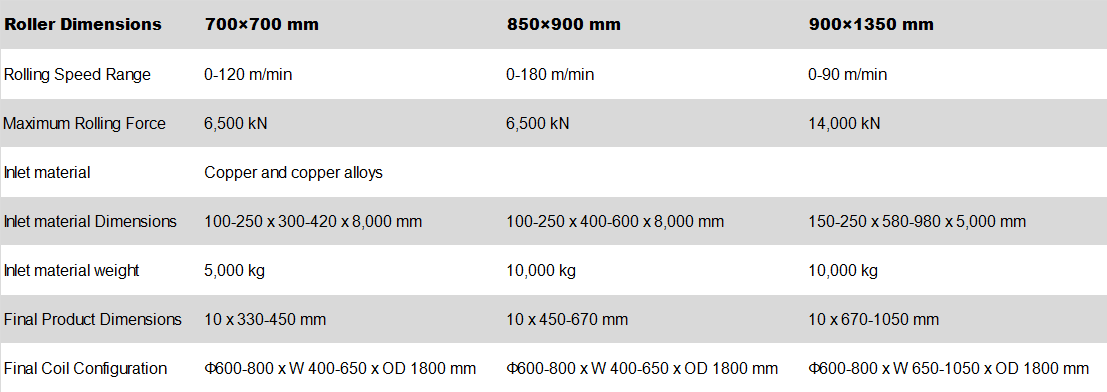

The Two-Roll Hot-rolling reversible Mill is primarily employed for the precision hot rolling of preheated copper and copper alloy ingots through bidirectional rolling passes. Following the rolling process, the produced plate is automatically coiled into finished coil form for further processing.

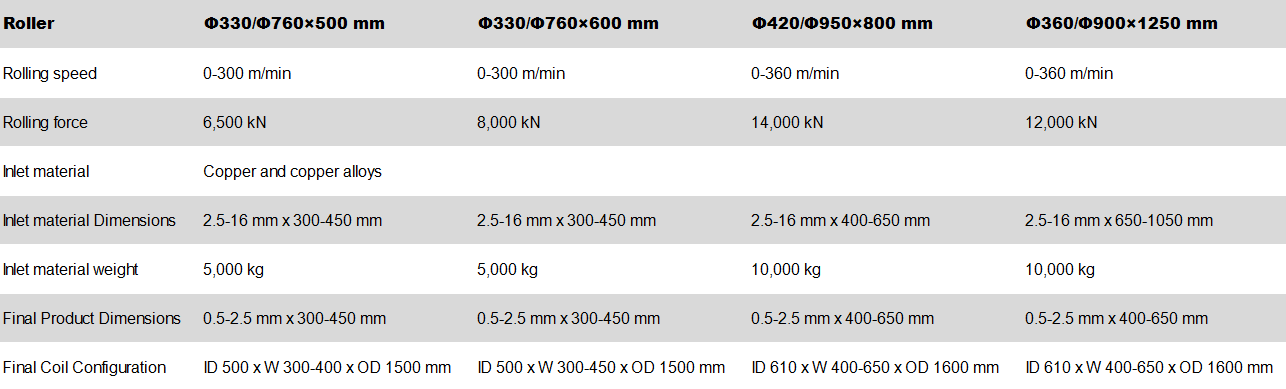

The four-roll hydraulic rough-to-medium rolling mill is specifically designed for the reversible cold rolling of annealed copper and copper alloys, followed by the formation of the finished products into coiled material for downstream processing.

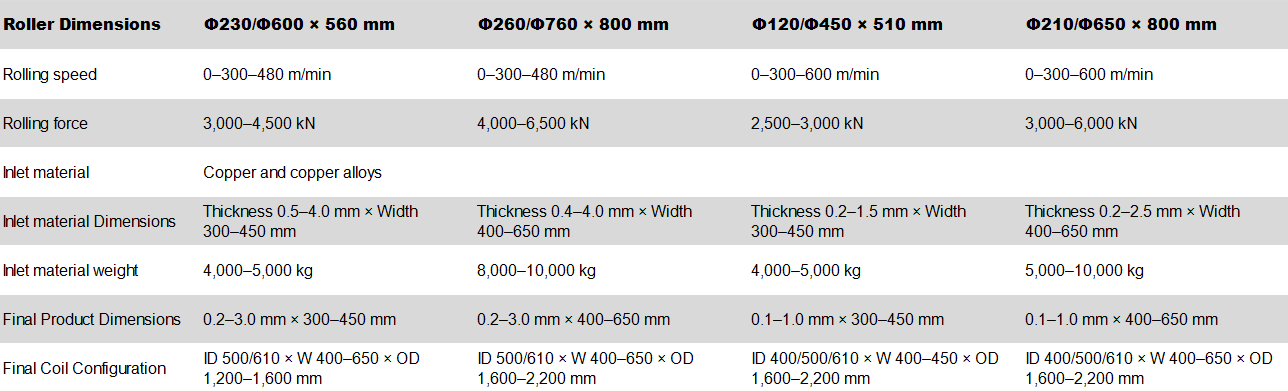

Four-roll hydraulic intermediate-to-finishing rolling mill: This unit is specifically engineered for the reversible cold rolling of annealed copper and copper alloys, with the subsequent coiling of the processed material into finished coil products.

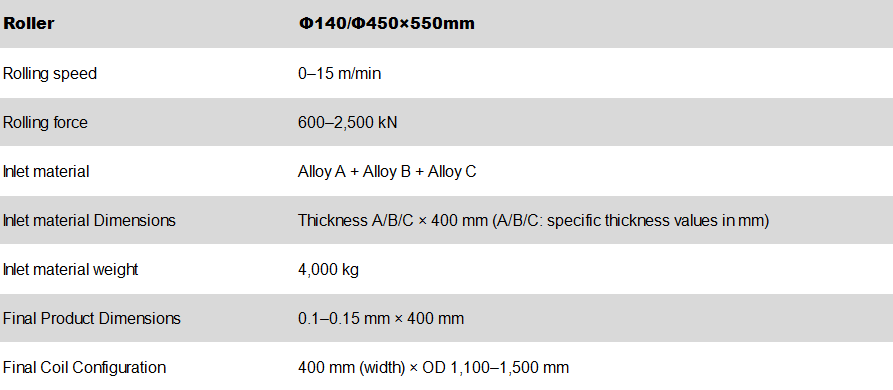

Four-roll composite rolling unit: Primarily designed for the consolidation of three-layer metallic structures—such as copper, copper alloys, and other alloy systems—this unit enables the production of integrated composite strips or foils, which are subsequently wound into coil form.

Copyright © 2025 HANYUAN·CLABO All Rights Reserved.