The three-roll planetary rolling mill is the most critical equipment in the copper tube casting and rolling production line. This equipment achieves a single-pass deformation rate exceeding 90% (elongation coefficient: 12–16), and the rapid compression process increases the temperature of the material to the point where dynamic recrystallization occurs. The rolled tube acquires fine equiaxed grains and remains in a soft state, providing excellent stretchability and superior wall thickness tolerance for subsequent drawing processes.

The latest-generation RM-90 /100 three-roll planetary rolling mill, developed by Clabo features optimized design and improvements, delivering high single-machine productivity, stable operation, and world-leading technical performance. Key features include:

Extended roller head lifespan through continuous design improvements. One set of roller heads can produce over 10,000 tons of copper tubes, requiring only replacement of wear parts like seals and bearings.

Enhanced cooling system improves roll life by optimizing temperature and friction conditions in the deformation zone. Efficient cooling also ensures refined grain structure in copper tubes.

Two operating modes: semi-automatic rolling and continuous automatic rolling.

Automatic online terminal cutting and hole-expanding devices significantly reduce labor requirements.

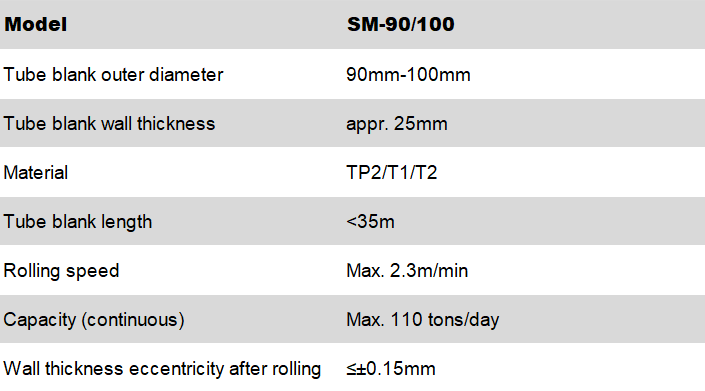

Main Technical Parameters of Three-Roll Planetary Rolling Mill

Copyright © 2025 HANYUAN·CLABO All Rights Reserved.