High-Speed Cold Pilger Mill

Our company has successfully developed a series of high-speed cold pilger mill machines designed for the production of precision cold-rolled tubes made from materials such as stainless steel, titanium, and titanium alloys. The finished tubes feature diameters ranging from Φ4 to Φ168 mm, wall thicknesses between 0.2 to 18 mm, surface roughness values of Ra ≤ 0.4–0.8 μm, and comply with international standards for shape and dimensional tolerances.

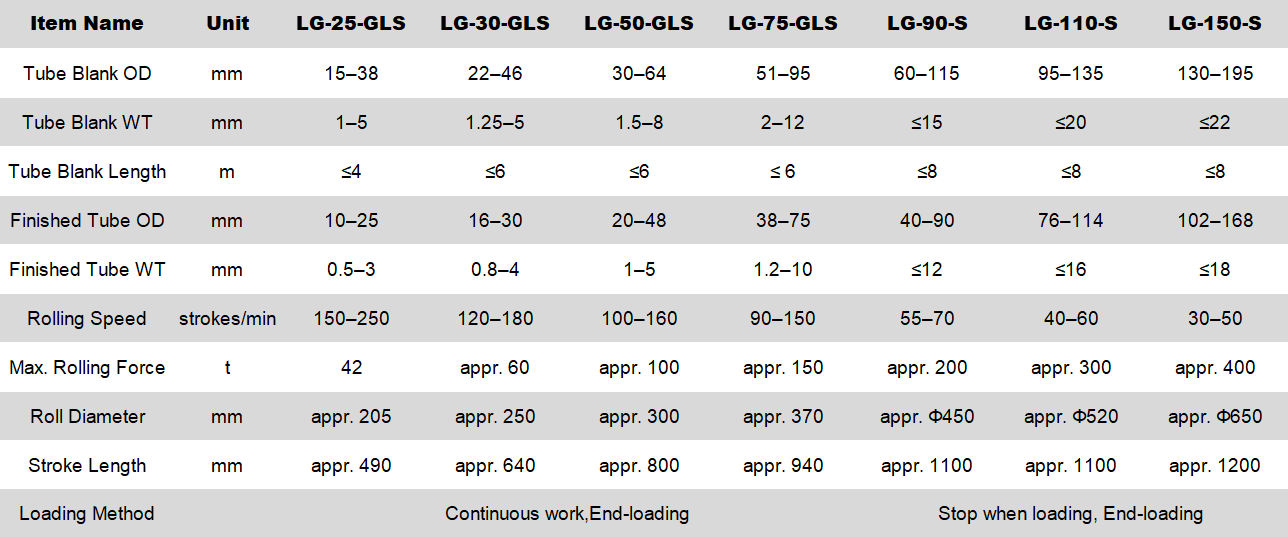

Clabo LG Series Two-Roll Cold Pilger Mills

Mark:

All models offer both stop-loading and continuous-loading versions. Process configurations allow either single/dual feeding and single/dual rotation as required.

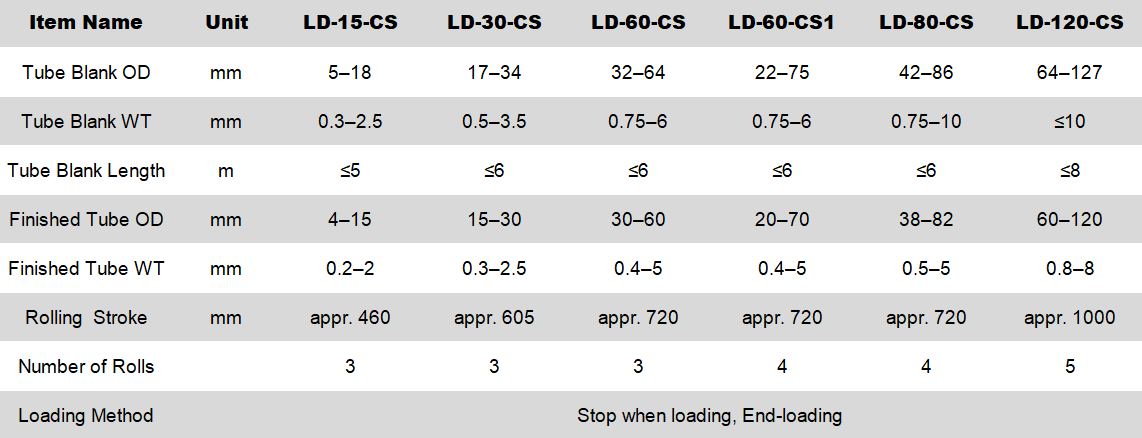

Clabo LD Series Multi-Roll Cold Pilger Mills

We specializes in manufacturing customized tube and bar straightening machines, providing straightening solutions and equipment. Key products include:

– Two-roller straightening: Features an upper concave and lower convex roller shape. Adjusting the roller angle changes the reverse-bending amount, suitable for bars and thick-walled pipes. Offers full-length straightening with a wide application range.

– Multi-roller straightening: Uses hyperbolic rollers to achieve reverse-bending through height differences. Common configurations: six rollers (2-2-2), seven rollers (2-2-2-1), ten rollers (2(5)), eleven rollers (2(5)-1). The seven-roller composite system (hyperbolic + deep/shallow concave rollers) is widely used for its superior straightening performance.

Working Principle of Roller-Type Straightening Machine

Round bars rotate and advance through a reverse-bending roller system. Uniform compressive bending deformation occurs in all circumferential directions, achieving straightening.

Key features:

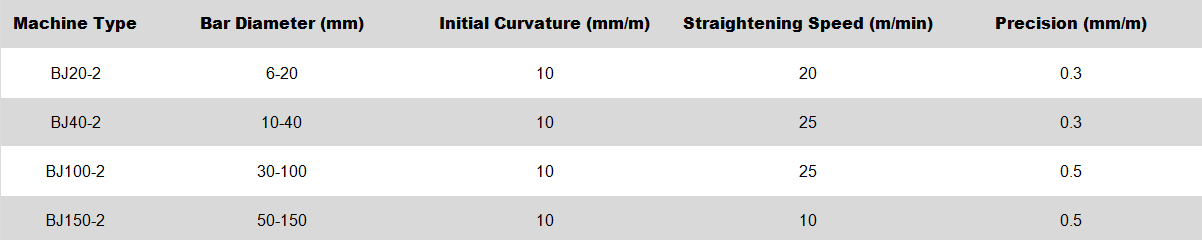

Two-Roller Bar Straightening Machine Parameters

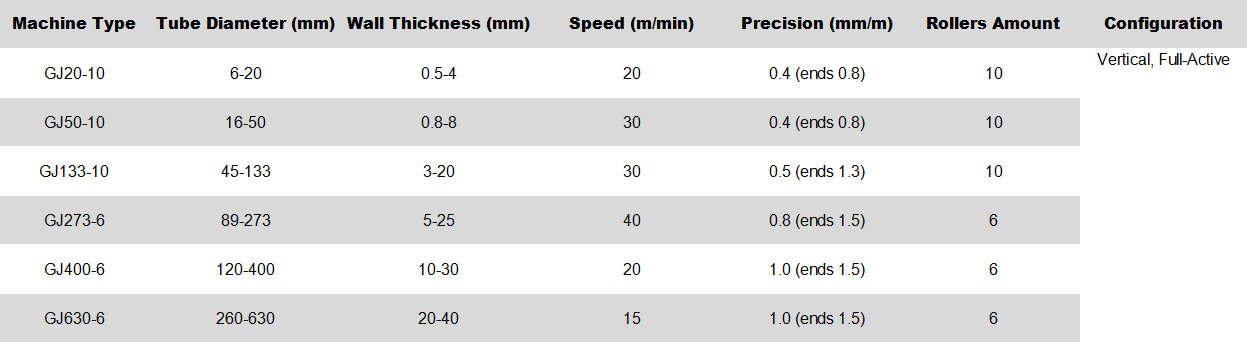

Multi-Roller Tube Straightening Machine Parameters

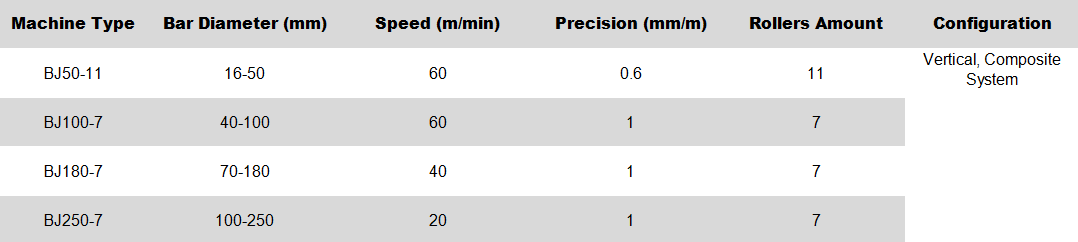

Multi-Roller Bar Straightening Machine Parameters

Copyright © 2025 HANYUAN·CLABO All Rights Reserved.