We specializes in manufacturing customized tube and bar straightening machines, providing straightening solutions and equipment. Key products include:

– Two-roller straightening: Features an upper concave and lower convex roller shape. Adjusting the roller angle changes the reverse-bending amount, suitable for bars and thick-walled pipes. Offers full-length straightening with a wide application range.

– Multi-roller straightening: Uses hyperbolic rollers to achieve reverse-bending through height differences. Common configurations: six rollers (2-2-2), seven rollers (2-2-2-1), ten rollers (2(5)), eleven rollers (2(5)-1). The seven-roller composite system (hyperbolic + deep/shallow concave rollers) is widely used for its superior straightening performance.

Working Principle of Roller-Type Straightening Machine

Round bars rotate and advance through a reverse-bending roller system. Uniform compressive bending deformation occurs in all circumferential directions, achieving straightening.

Key features:

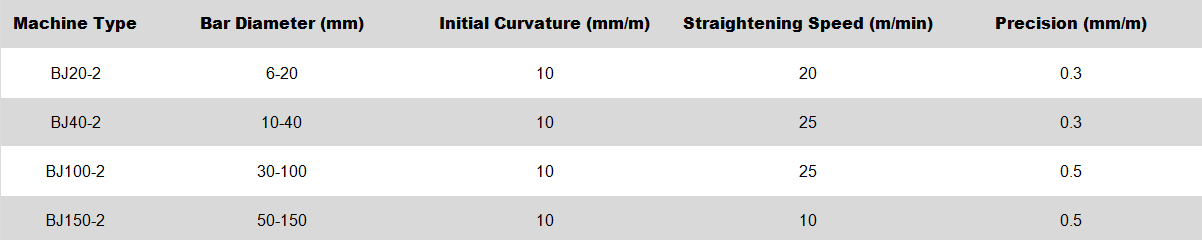

Two-Roller Bar Straightening Machine Parameters

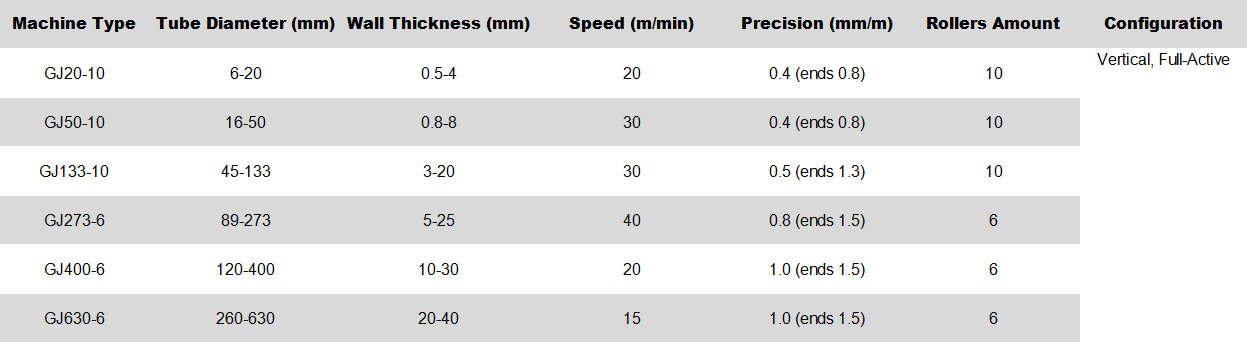

Multi-Roller Tube Straightening Machine Parameters

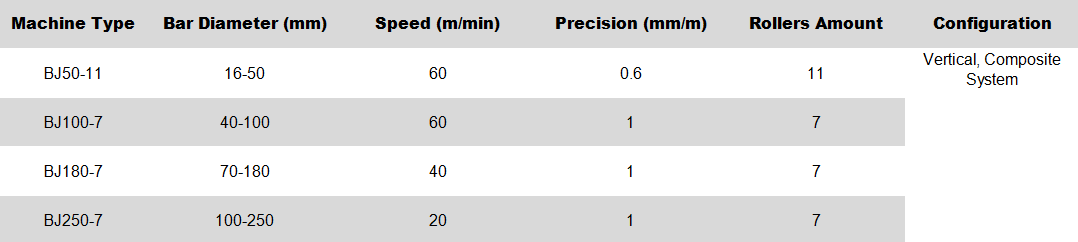

Multi-Roller Bar Straightening Machine Parameters

Copyright © 2025 HANYUAN·CLABO All Rights Reserved.