The new-generation Surface Milling Machine developed by CLABO serves as specialized equipment for removing oxide scale from the outer surface of tube blank in copper tube casting and rolling lines. It employs a straightening and milling surface technology, which is protected by independent intellectual property rights, to remove the oxide scale in a single pass. This significantly enhances both product yield and milling surface quality. The unit comprises a feeding system, planetary milling machine, discharging system, and is integrated with corresponding electronic control, hydraulic, lubrication, pneumatic, and cooling systems.

Main Features of the Equipment:

(1) One-key operation enables the automatic milling process, including feeding, milling, and discharging.

(2) The application of straightening and sizing technology ensures excellent straightness and roundness of the tube blank while minimizing the milling volume.

(3) An optimized internal and external guiding system eliminates vibration during milling, resulting in superior roundness and high surface quality of the finished products.

(4) The milling cutter is infinitely adjustable, allowing a single cutter to mill varying thicknesses of the tube blank’s surface.

(5) The copper chip collection device can be equipped with a drag chain walking mechanism featuring a drying function.

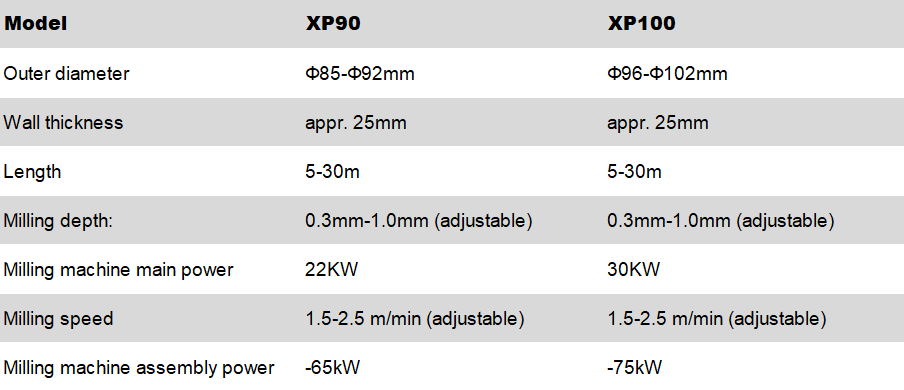

Key equipment parameters are provided below.

Mark: Customization can be made for different materials and outer diameters as per requirements.

Copyright © 2025 HANYUAN·CLABO All Rights Reserved.